Stock image Non Destructive

Close Up View Of The Manual Industrial Ultrasonic Inspection For Weld Metal. Conventional Ultrasonic Testing Limits Thicknesses That Can Be Examined To Less Than 8 Mm.

Image, 6.56MB, 4773 × 3182 jpg

Vector Monochrome Flat Design Icon Of Thickness Measurement. Blue Isolated Symbol.

Vector, 5.14MB, 8334 × 8334 eps

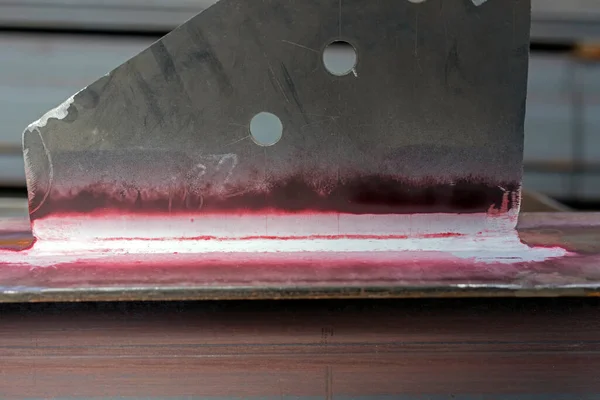

View Of The Crack Between Weld Metal And Base Metal ( Heat Affected Zone, Haz) And Magnetic Particle Inspection. It Is A Crack That Forms A Short Distance Away From The Fusion Line. Ndt, Asme, Astm.

Image, 12.72MB, 5439 × 3627 jpg

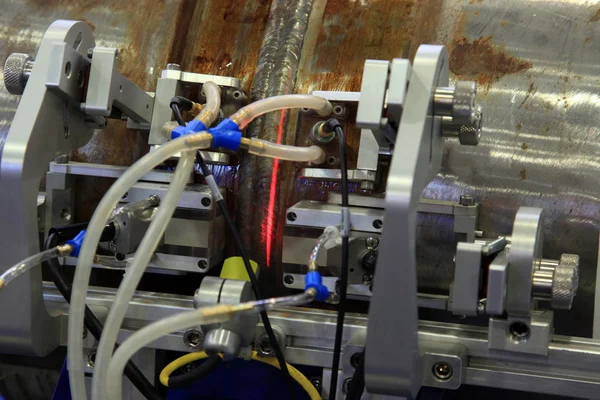

Engineer Is Inspection To Pipe Welds With Ultrasonic Testing. Reflected Ultrasound Comes From An Interface, Such As The Back Wall Of The Object Or From An Imperfection Within The Object.

Image, 16.33MB, 6324 × 4216 jpg

Vector Monochrome Flat Design Icon Of Thickness Measurement. Blue Isolated Symbol.

Vector, 5.14MB, 8334 × 8334 eps

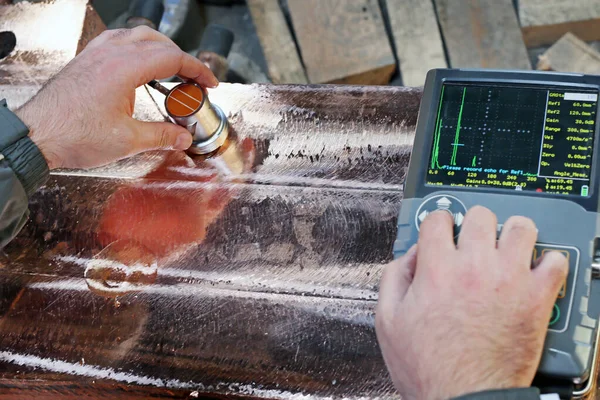

Engineer Is Inspection To Pipe Welds With Ultrasonic Testing. Reflected Ultrasound Comes From An Interface, Such As The Back Wall Of The Object Or From An Imperfection Within The Object.

Image, 9.05MB, 6720 × 4480 jpg

Crack Steel Butt Weld Carbon Background Green Contrast Of Magnetic Filed Fluorescent Test

Image, 28.14MB, 5760 × 3840 jpg

Ultrasonic Or Ultrasound Testing To Copper Casting Material. A Common Example Is Ultrasonic Thickness Measurement, Which Tests The Thickness Of The Test Object.

Image, 7.36MB, 6720 × 4480 jpg

Step To Use Spray White Contrast On The Welded Surface Before Performing Non-Destructive Testing(NDT) With Process Magnetic Particle Testing(MT).

Image, 8.05MB, 6000 × 4000 jpg

Checking Defect In Welded Of Steel Add Joint With Process Ultrasonic Testing (UT) Of Non-Destructive Testing(NDT) At Industrial Factory.

Image, 12.63MB, 6000 × 4000 jpg

Technological Pipelines DN50 And DN 150 Make A Turn By Means Of Bends In The Trench And Approach The Well

Image, 19.46MB, 6000 × 4000 jpg

Paint Inspector Is Measuring To Red Colored Paint Coating Of The Pipe In Construction Site. A Coating Is A Covering That Is Applied To The Surface Of An Object, Usually Referred To As The Substrate.

Image, 12.26MB, 6720 × 4480 jpg

Checking Defect In Welded Of Steel Add Joint With Process Ultrasonic Testing (UT) Of Non-Destructive Testing(NDT) At Industrial Factory.

Image, 12.33MB, 6000 × 4000 jpg

Engineer Is Inspection To Pipe Welds With Ultrasonic Testing. Reflected Ultrasound Comes From An Interface, Such As The Back Wall Of The Object Or From An Imperfection Within The Object.

Image, 7.75MB, 5866 × 3910 jpg

Ultrasonic Or Ultrasound Testing To Copper Casting Material. A Common Example Is Ultrasonic Thickness Measurement, Which Tests The Thickness Of The Test Object.

Image, 12.47MB, 5738 × 3826 jpg

View Of The Nondestructive Testing Methods With Multiple Photos. Nondestructive Testing (NDT) Is A Wide Group Of Analysis Techniques Used In Science And Technology Industry To Evaluate.

Image, 4.7MB, 4160 × 2773 jpg

Dye Penetrant Inspection (DP), Liquid Penetrate Inspection (LPI) Or Penetrant Testing (PT) To Carbon Steel Welds. The Penetrant May Be Applied To All Non-ferrous Materials And Ferrous Materials. Ndt, Penetration.

Image, 12.25MB, 6720 × 4480 jpg

Ultrasonic Or Ultrasound Testing To Copper Casting Material. A Common Example Is Ultrasonic Thickness Measurement, Which Tests The Thickness Of The Test Object.

Image, 11.07MB, 5461 × 3641 jpg

View Of The Longitudinal Crack In The Heat Affected Zone (top Welding Edge) With Liquid Penetrant Testing Method Of The Nondestructive Testing.

Image, 12.13MB, 5131 × 3421 jpg

Checking Defect In Welded With Process Magnetic Particle Testing(MT) Of Non-Destructive Testing(NDT) At Industrial Factory.

Image, 10.56MB, 6000 × 4000 jpg

Non-destructive Testing Of Welded Joints Of The Du 80 Pipeline At The Construction Of An Oil Refinery. X-ray Control Of Welding.

Image, 12.29MB, 6000 × 4000 jpg

Inspector Use Ultrasonic Testing Machine For Inspection Defect In Steel Structure.

Image, 2.82MB, 4000 × 3021 jpg

Magnetic Particle Testing (MPT), Or Magnetic Particle Inspection, Is A Non Destructive Examination (NDE) Technique Used To Detect Surface And Slightly Subsurface Flaws In Most Ferromagnetic Materials.

Image, 4.45MB, 3210 × 2141 jpg

Inspector Use Ultrasonic Testing Machine For Inspection Defect In Steel Structure.

Image, 2.25MB, 4000 × 2880 jpg

Checking Defect In Welded With Process Magnetic Particle Testing(MT) Of Non-Destructive Testing(NDT) At Industrial Factory.

Image, 9.46MB, 4000 × 3000 jpg

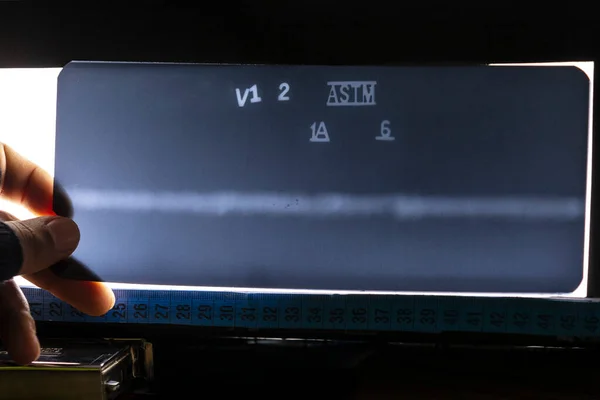

The Radiography Film Operator Level 2 Evaluation Radiographs Of The Welds With Viewer And He Is Writing Some Reports. The Weld Metal Has Some Defects (Tank: Storage Tank, ASTM 1A And 6: Penetrameter).

Image, 5.24MB, 3861 × 2574 jpg

Checking Defect In Welded With Process Magnetic Particle Testing(MT) Of Non-Destructive Testing(NDT) At Industrial Factory.

Image, 9.98MB, 6000 × 4000 jpg

Inspector Is Measuring Thickness Of The Pipe Material From Near To Weld With A Portable Ultrasonic Wall Thickness Measurement Gauge. It Is A Method Of Performing Non Destructive Measurement (gauging).

Image, 13.54MB, 5657 × 3771 jpg

Non-destructive Testing Of Welded Joints Of The Du 200 Pipeline At The Construction Of An Oil Refinery. Specialist Indicates Weld For X-ray Inspection Of Welding.

Image, 9.76MB, 5759 × 3840 jpg

Step To Use Spray White Contrast On The Welded Surface Before Performing Non-Destructive Testing(NDT) With Process Magnetic Particle Testing(MT).

Image, 13.74MB, 6000 × 4000 jpg

Engineer Is Inspection To Pipe Welds With Ultrasonic Testing. Reflected Ultrasound Comes From An Interface, Such As The Back Wall Of The Object Or From An Imperfection Within The Object.

Image, 11.97MB, 6720 × 4480 jpg

Page 1 >> Next